Gene Berry takes his new Shanteuse out for a spin on a Missouri lake.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Nov09)This issue will dig deeper into ballast requirements. The 1 December issue will complete the topic.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Gene Berry takes his new Shanteuse out for a spin on a Missouri lake.

|

|

|

NOW, WHERE WAS I.....

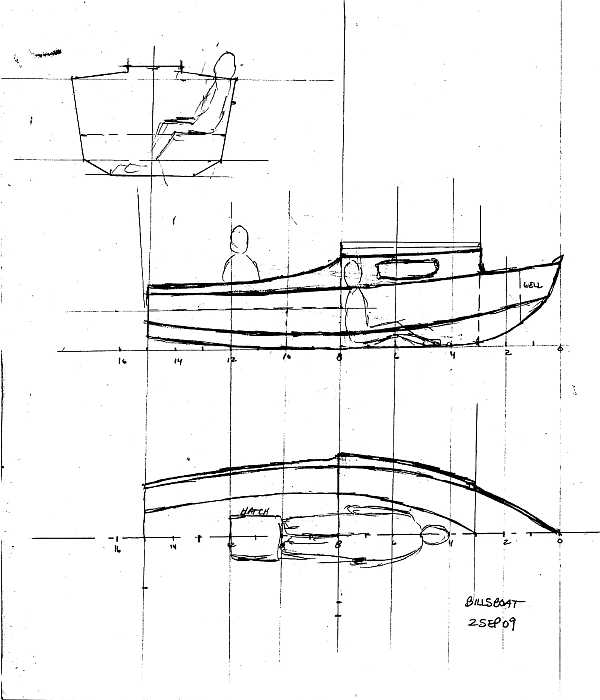

...To recap we were plugging away at a tough assignment of a small but heavy cruiser. In the first stage it looked like this:

There was an agreement between myself and the skipper that it would be a one man boat on a cruise. He did not want to haul a lot of ballast around and was willing to accept a boat that would self right on its own in a knockdown as long as the skipper hopped overboard as it went to 90 degrees, thus relieving the hull of some weight up high. Then the boat would self right and the skipper has to climb back on somehow. If we needed the ship to self right with the skipper in place a few hundred more pounds of ballast would be required to balance his weight and the skipper said he would rather swim than haul around lead.

The design progressed to where I had drawn the panel expansions and made a card model:

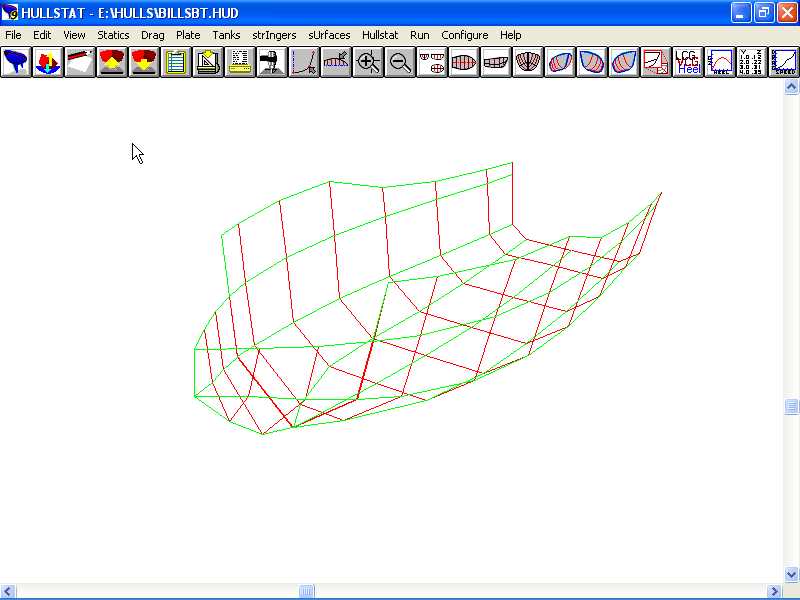

And made a Hullform model to get a good hack at where the center of gravity (cg) had to be for the boat to self right from 90 degrees.

BALANCE POINT...

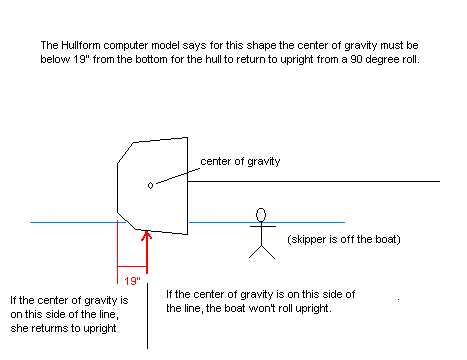

The Hullform model said the boat will self right from 90 degrees of roll if the cg is at 19.0", or below, measured from the bottom of the hull. So imagine the hull balanced on an edge like this:

Now it becomes a question of doing a weight and balance estimate for the design and find a ballast weight and location that will give us the cg at 19" from the bottom.

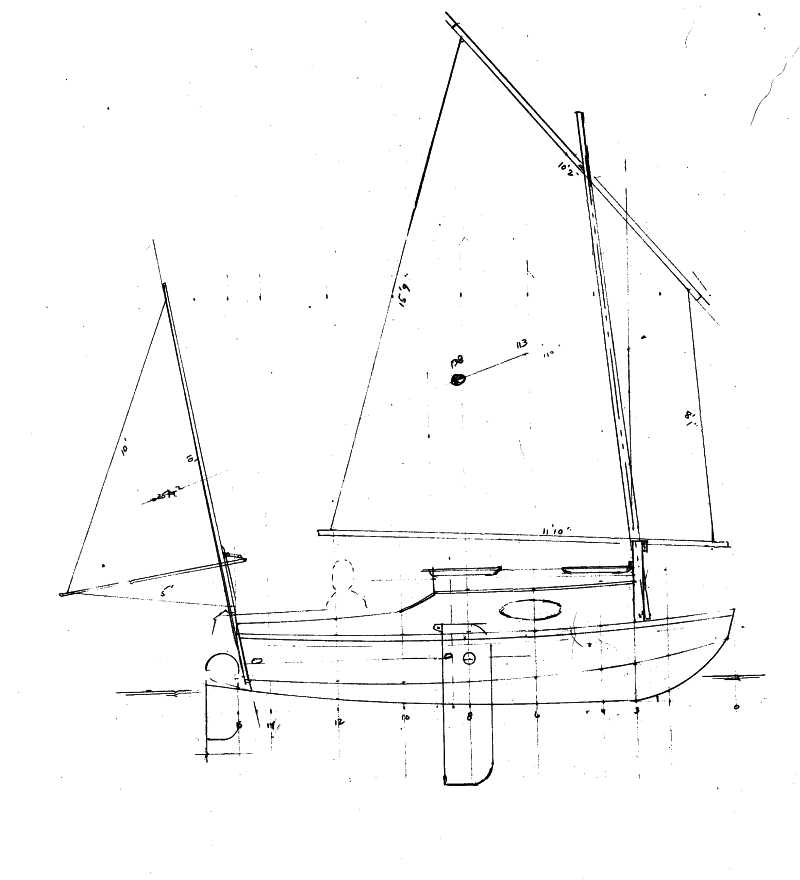

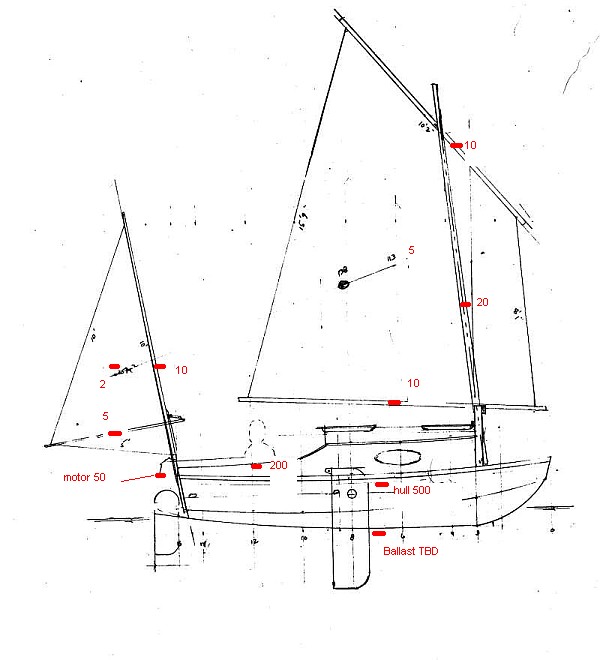

To progress you need to have a drawing of the boat with a sail rig up and really an estimate of everything that will be in the boat. At this time I had a sail rig which used the same sails the skipper had for his present boat:

Now to paste in the weight guesses. Like this:

There can be a lot of gosh and golly hand waving, on top of pure ignorance, in a job like this. The sail rig isn't too bad in that you can take the yard, for example, say it is 2" round and 11' long and that makes it 414 cubic inches in volume. Typical wood might weigh .017 pounds per cubic inch (say 25 or 30 pounds for a cubic foot with a lot of variation) so you guess the yard will go about .414x.017=7 pounds or so. I've guessed 10 here being rational and conservative in engineering nature anyway and note that there are some ropes and pullies up there too and that I like round numbers. But you see how it is pieced together a step at a time. When I first worked at the missile factory I wondered how the weights engineers did their work and the answer is slowly and meticulously....calculating shapes and volumes and keeping ponderous track of rivets and rivet holes. But they did something I am copying here in estimations in the first stages. As Harry once said, "We always know how much it weighs. We just don't know where the weight is. Yet!".

An example of that is in the gross hull estimate of 500 pounds. Well, it will be more than 300 and less than 800 if it goes by the plans. But as the design progresses we can refine that weight and its location on the cg diagram and refine our ballast estimates with it. At this stage it is a guess.

Next...

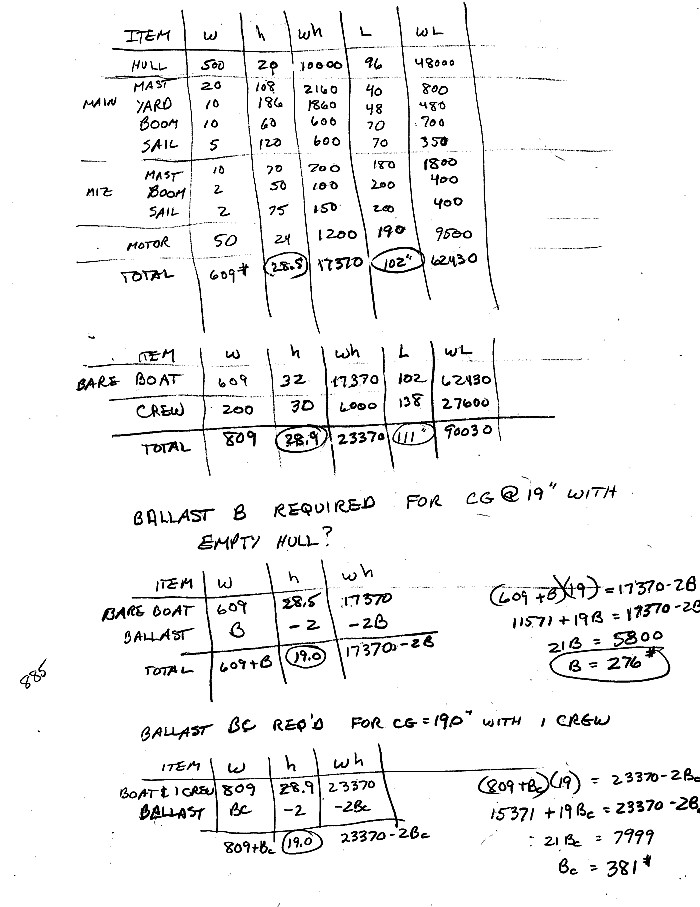

...using the above scale model we measure upward from the bottom, which is here our baseline and datum line, and make a chart of it all with all the elements, with weight and height above the baseline, and find the cg location which might be thought of as the "average" location of all the weights together. Here is my chart:

There you have it. The "h" is the distance from the datum to the item. I've also figured the "L" which would be the distance from the bow tip to the item so I can get the horizontal location of the cg also and maybe can trim the boat level by also getting the ballast located best fore and aft. Anyway, the bare boat (with a 50# motor) looks here to weigh 609 pounds and the cg is 28.9' above the datum, well above the 19" desire. You can look at the chart and see that the hull itself and the main mast are the main contributers to the high up cg. No surprise there.

I've also shown in a separate calculation the cg location with a 200 pound skipper on the aft deck. Turns out I've placed him pretty much on the average for the boat so the vertical cg hasn't moved much but his weight aft moved the logitudinal cg aft.

NOW THAT NASTY BALLAST...

The plan is to bolt the ballast in lead bars to the bottom of the hull so that its average location will be at -2". The bottom of the calculation page shows the algebra. To get the cg down to 19" takes 276 pounds of ballast at -2".

Now before we fly off the handle about how I thought it would be less, I say it still will, in the end, be less than 276 pounds of lead. Here is why. As the structure is better defined the hull weight, given at first guess as 500 pounds 20" up, will be broken down into smaller pieces more accurately located. In particular this boat is to have a very thick plywood bottom, at least an inch thick. So I expect maybe we will have a hundred pounds of plywood there which will come right off the lead weight. I hope.

Even without that idea we are still in business I think. Total boat weight ready to go will be about 900 pounds on the trailer. And with the skipper and his lunch we might be 1200 pounds sitting in the water.

And let's look at the lead requirements if the skipper wants to stay on board for his knockdown. Now we need another 100 pounds plus to balance his weight as he sits on the aft deck. If he stands up all bets are off. Figuring ballast to counteract live folks on deck is just a dice throw. No telling what they will do at the time and their weight in a small boat is major portion of the total.

In the same way it appears that you would need another 100+ pounds of lead to counteract the weight of crew in general sitting on the aft deck. If you want self righting with say three 200 pound men you will need over 300 pounds of extra lead down low, the total adding about 1000 pounds to the floating weight of the boat. Now we are over 1600 pounds which was the original plan. The boat will float that weight. The original goal at that weight was for "reasonably good flow lines" which to me means the transom and chines are just starting to touch the waterline. She will float a lot deeper than that, just slower. Total weight sitting on the trailer would then be about 1000 pounds with about 40 percent of that in lead down low and if you read the old time books you might think I have reinvented the old "40 percent" rule.

HERE IS SOMETHING REALLY IMPORTANT...

...if you read the old books you might also find that "self righting" means a lot of different things. To Howard Chapelle it meant for a sharpie to recover from a 45 degree heel. I am pretty sure that is not good enough. For an ocean sailor I think it means recovery from a 140 degree roll or even a full 180 degree roll (one reason I'm not an ocean sailor). I've chosen 90 degrees. I have found that OK for the usual small boat sailing. A boat with wooden spars will not in my experience turn turtle even if it goes past horizontal because the wooden spars have emergency flotation way out from the hull. But the boat may lay stable on its side, especially if the sails absorb water. Not that I'm trying to scare anyone. But you need to know.

Believe it or not I still have words to write about this. I think next time I will do the more refined hull cg effort and show my idea of the ballast installation.

Caprice

CABIN SAILBOAT, 25' X 6', 900 POUNDS EMPTY

About 15 years ago I built a Payson Canoe and used it for several years before selling it. I replaced it about 10 years ago with my Toto double paddle canoe. Toto has the same multichine cross section as the Payson Canoe but I tried for a long lean bow which would be better in rough water and more foregiving of bow down trim. I still have that Toto, unchanged in any way since new, and still use it all summer. Amanda Johnson demonstrates:

The Toto shape worked so well that I used it in other designs like Roar2 and RB42. I tried it also in a sailing boat, the 20' Frolic2 (the original Frolic was narrower, more of a rowboat than a sailboat). Frolic2 was unballasted with a small cuddy and I hoped it would be a good daysailer and one man camping boat.

Bill Moffitt had built my Woobo design and funded a 20% enlargement of Frolic2 that would have a cabin, water ballast, and a yawl rig for cruising near the Gulf Coast.

The 20% enlargement idea went very well except that I had to deepen the hull more than that to give some serious headroom in the cabin, but it doesn't have standing headroom. Great empasis was placed on ease of use and rigging. The main mast is short and stepped in a tabernacle. There is a draining anchor well in the bow, a small storage segment under the front deck. The mast tabernacle is bolted to the bulkhead that forms the front of the sleeping cabin. There is a utility room aft of the sleeping room. Water ballast tanks are under the bunks and in the sides of the utility room floor, about 600 pounds of ballast as I recall. Aft of the cabin is the self draining raised cockpit with storage volume under the deck. Finally there is a self draining motor well across the stern. Construction is taped seam plywood.

Bill couldn't start his Caprice right away but Chuck Leinweber of Duckworksmagazine gave it a try. He has the room and tools and smarts to tackle a project like this with no hesitation. There weren't many changes from the plans that I know of, the main one being adding a conventional footwell to the aft deck which is designed to have a hatch type of foot well as with the Bolger Micro.

Chuck trailered his Caprice up from Texas to our Midwest Messabout this June and I had a chance to go over it, sail it for a couple of hours, and watch it sail from other boats. Wonderful!

Chuck tells me it takes less than 15 minutes to rig the boat to as you see here. As shown the boat has its ballast so you see it beaches very well indeed. I asked about the ballast. He can flood the tanks without power, just open the access plate, reach in and pull the fill plug and let the water rush in. Since the tops of the tanks are about even with the normal waterline he has to move his weight around to keep the tank depressed long enough to completely fill. Then you reach into the filled tank, replace the plug in the bottom, and then replace the access plate in the top. There are two tanks to fill.

Are the ballast tanks worth the building effort? On a multichine hull like this the tops of the tanks form flats that give places for bunks and storage so that is good. When full the boat should have a very good range of stabiltiy. Chuck's boat has never been in rough going as I'm writing this so the effect of the ballast remains to be proven. It has been capsized in a practice but the ballast tanks were empty and the boat was empty with no crew, etc.. But the ballast is a success from the standpoint that Chuck is able to tow his Caprice behind a four cylinder pickup truck. My idea was to pull the boat up the ramp and drain the tanks afterward by simply pulling the drains plugs. But Chuck has found it best by far to empty the tanks before recovering the boat at the ramp. So he uses a bilge pump in each tank to pump them empty. I'd be worried about water ballast tanks on a wooden boat from a rot standpoint and would be careful to open all the plugs and access panels when the boat is stored.

(I should add that I think an empty Caprice will weigh about 900 pounds based on the plywood sheet count (eight sheets of 1/4", nine sheets of 3/8" , five sheets of 1/2" and one sheet of 3/4"). But any boat like this can hold an awful lot of gear and junk.)

Caprice has the tabernacle setup that I first saw on Karl James' sharpie. The mainsail is 190 square feet, balanced lug. The mast is fairly short, stowing within the length of the boat when lowered. Chuck demonstrated putting up the mast, maybe a 15 second operation. I've been drawing these for a while on different boats but this is the first one I know of to get built and used. I'm greatly relieved that is all works so well. Before you decide to tack a tabernacle like this onto your boat, be advised that the tabernacle posts go clear to the hull bottom with big bolts all around a beefy bulkhead.

I thought Caprice sailed very well in the light winds we had that weekend. Tacked very smoothly through 90 to 100 degrees which is all you can ever get with a low tech rig. Very smooth and quiet compared to the sharpies I'm used to. It didn't seem at all sensitive to fore-aft trim. In the light winds it went 5 knots on the GPS which is certainly fast for the conditions.

Well, all in all I thought Caprice was everything I was hoping for.. Plans are $45.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the "ketchooner" rig, featuring his own polytarp sails, that is shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Batista's of www.breakawaybooks.com, printer of my book and Max's book and many other fine sports books. Boat is done, shown here off Cape Cod with mothership Cormorant in background, Garth's girls are one year older. Beautiful job! I think Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat.

And a new Down Under Blobster is off cruising under outboard power as it waits for its sailrig.

A view of the Caroline prototype showing a lot of the inside, crew on fore deck. Beautiful color:

And here is another making I think its maider voyage in the Texas 200. (I'm told the Chinese rig will be replaced by the blueprint rig.)

I gotta tell you that on the Caroline bilge panels I made an error in layout and they are about 1" too narrow in places on the prototype plans. I have them corrected but it always pays, even with a proven design, to cut those oversized and check for fit before final cutting.

And a Deansbox seen in Texas:

And in Texas Gordo Barcom has completed the first Laguna and I hope to give a full report soon. Here he blasts along on his first flight:

The Leinwebers have ganged up on me to rename the Sandrasboat to RioGrande. And here is a photo of Sandra in her RioGrande on the Rio Grande. We have to sort out some fit problems Chuck reported he had in building but then it will go public. It is essentially a decked Toto.

A Twister goes together in good shape:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)